Description

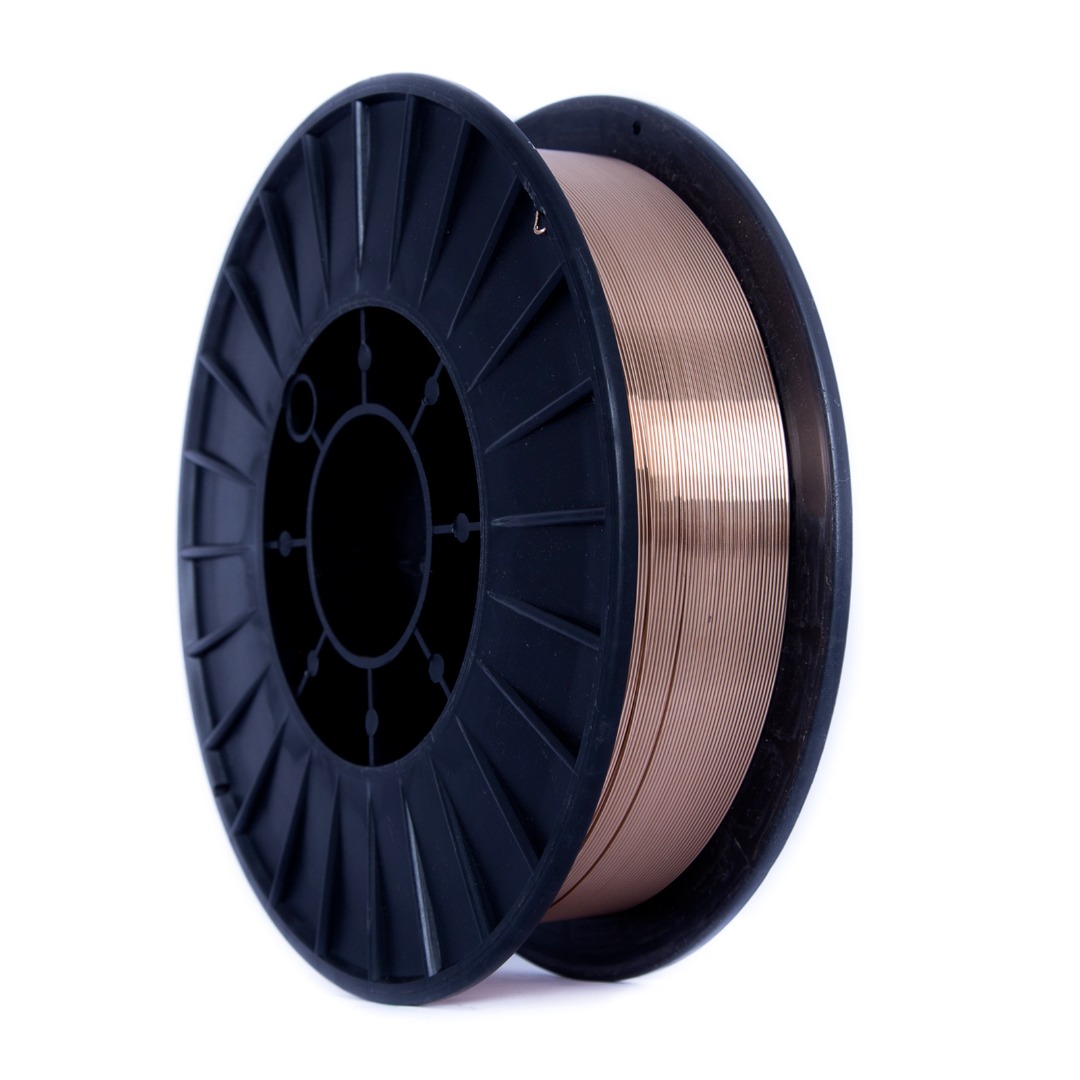

MAG shielded welding wire

MAG welding wire is a type of silicon manganese alloy welding wire in two types with copper coating and without copper coating (ER70S-6, G3Si1) which is used for welding metal arcs with GMAW shielding gas.

MAG welding wire is a kind of silicon magnesium alloy in two types with and without copper coating that being used in welding metal arc with GMAW protective gas.

Welding current: +DC

Shielding gas: Pure CO2 or mix (80% Ar + 20% CO2)

Advantages:

- Great start

- Wireless feeding at high speeds

- Long feeding intervals

- Very stable arc at high current intensities

- Low vapor emission

- Reduce erosion on the wire contact surface inside the nozzle

- Proper protection of the wire against corrosion

Applications:

- Construction steels

- Fine-grained steels

- Pipe steel

- Boiler steels and pressure vessels

- High temperature steels

- Shipbuilding steels

- Casting steels

Chemical composition of welding wire:

S: 0.035 MAX P: 0.025 MAX Mn: 1.40-1.85 Si: 0.80-1.15 C: 0.06-0.15

Mechanical properties of pure weld metal:

Tensile strength (MPa): 480min Stretch percentage: 22min Surrender pressure (MPa): 400min

| Voltage (v) | Current (A) | Wire diameter | Arc type |

| 11-9 | 25-85 | 0.80 | Short Arc |

| 20-24 | 110-150 | 1.00 | Short Arc |

| 17-28 | 230-285 | 1.20 | Short Arc |

| 35-44 | 280-340 | 1.20 | Short Arc |

| 35-44 | 280-480 | 1.60 | Short Arc |

Reviews

There are no reviews yet.